Born Prolamex / Guantes Altex

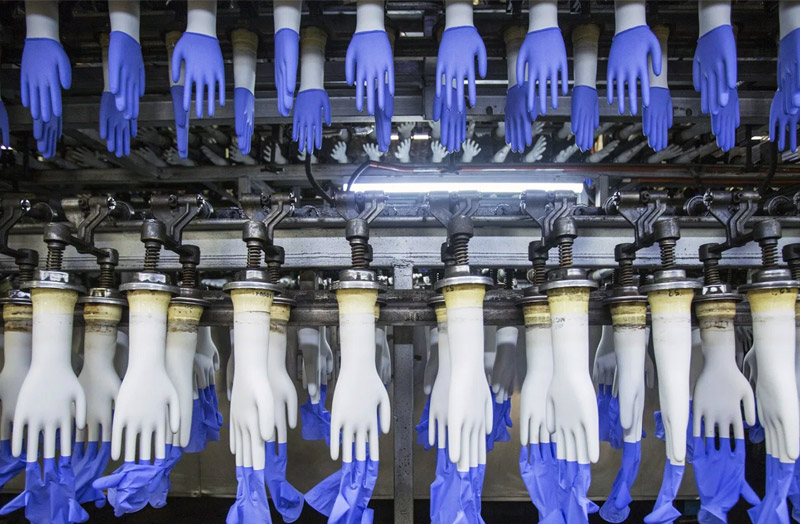

With only 3 artisanal production lines attended by 6 employees.

With only 3 artisanal production lines attended by 6 employees.

Monthly production of domestic gloves and swimming caps (15,000 units)

Production lines with more than 120 workers operating them

Our production is certified by the Mexican standard NMX-S-039-SFCI-2000

Average production of 70,000 gloves/day = 1.8 millions per month

Altex Gloves begins participation in the North American market

Altex gloves continue to innovate in their formulas, packaging and designs to offer excellent comfort and protection in all their models.

We are pleased to announce that we have obtained ISO 9001:2015 standard

We are proud to have added one more piece to our standard portfolio, confirming our mission to maintain a high level of quality.

In ALTEX PRODUCTS MÉXICO, S. de R.L. de C.V. we manufacture protective gloves for domestic and industrial use, we are committed to the satisfaction of our stakeholders through the implementation, maintenance and continuous improvement of the Quality Management System according to the requirements established in the Official Mexican Standard NMX-S-039-SCFI-2000, ISO 9001:2015 y Buenas Prácticas de Manufactura , promoting: